Touche Soft-Pro

Touche Soft-Pro

Designed for the fabric types that are not suitable for conventional calendering. Rubber blanket machine allows you to get bulky and soft effect with a touch of shine coming from heated chrome roller. Specially designed to work as a conventional two roll calender with extra rubber blanket application to get softer effects on the fabric.

Touche S-Pro

Touche S-Pro

As Polteks, we keep up with the innovations in the textile industry in line with the developing technology. This S-Roll System integrated versatile calender type will provide you with control roll deflection to get even nip pressure line with all types of fabric.

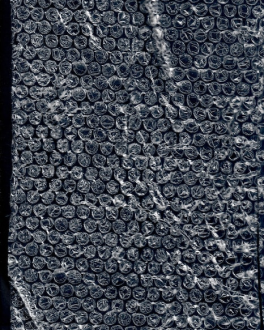

Blanket

Blanket

As Polteks, with the specially developed rubber blanket in the calender machine with rubber blanket, we have made it possible to apply the calender process to fabric types that are not suitable for the calender process under normal conditions and to obtain different touches for many fabric types. In fact, at high temperatures that can be increased up to 160 ° C, both a shiny effect on the surface of the fabric and a draped structure in the fabric can be obtained.

Touche Nip-Pro

Touche Nip-Pro

Developments in the textile industry come with greater requirements about the quality of the final product. Nippol system allows you to get more reliable fabric calendering results.