Blanket

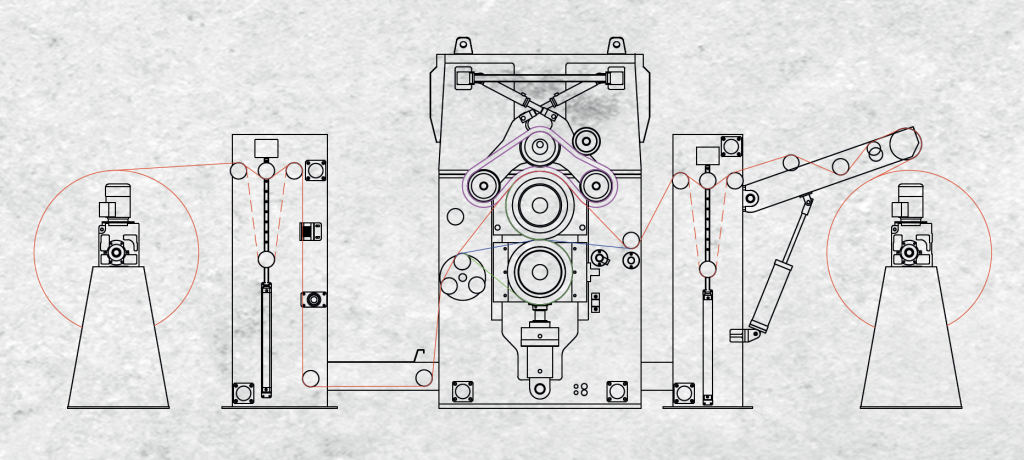

Kauçuk Blanketli Kalender Makinaları

As Polteks, with the specially developed rubber blanket in the calender machine with rubber blanket, we have made it possible to apply the calender process to fabric types that are not suitable for the calender process under normal conditions and to obtain different touches for many fabric types. In fact, at high temperatures that can be increased up to 160 ° C, both a shiny effect on the surface of the fabric and a draped structure in the fabric can be obtained.

Advantages of POLTEKS Calenders

| Shirting Fabrics | Home Textile Fabrics (curtains, tulle and upholstery) |

| Home Textile Fabrics (duvet covers, sheets) | Clothing Fabrics (pants, jackets and outerwear) |

| OPTIM | DELUXE | DELUXE PLUS | |

| Maximum working force /Maximum working pressure(kg/cm) | 300 | 500 | 500 |

| Working speed / Working speed (m/min) | 5-90 | 5-90 | 5-90 |

| Maximum fabric width / Maximum working width(mm) | 3800 | 3600 | 3600 |

| Maximum operating temperature / Maximum operating temperature (C°) | 200-250 | 200-250 | 200-250 |

| Poliamid silindir tipleri / Poliamid silindir tipi | Klasik / S-Roll / Nippol | Klasik / S-Roll / Nippol | Klasik / S-Roll / Nippol |

| Entry | A-Frame, Plaiter, Central Unwinding |

| Exit | A-Frame, Plaiter, Central Winding |

| Seam Control System | Preceise Seam Control System |

| Metal Detector | Detecting All Types of Metals |

| Tension Control System | Could be integrated to the exit and entry of the machine depending on the need of customer |

| Salvage Shifting System | Moves the fabric left and right to prevents the edges from becoming thick during winding the fabric |

| Edge Holding System | Ensures the fabric to pass through the rollers continuously in straight form. |

| Cooling Rollers | Depending on the fabric passing rollers can be located at the exit or in between the nips |

| Sleeve Cooling System | Cools the sleeve which is in constant contact with the heating chrome roller to prevent deformations on the sleeve |

| Air Permeability System | Inline traversing air permeability system reads air permeability value constantly |

| Reconditioning | Renewing your old machinery to be brand new with hydraulic unit, electrical cabinet, roller maintanence |

We focus on providing our partners with the latest technologies and innovative solutions for a sustainable textile industry for the future.

DISCOVERY