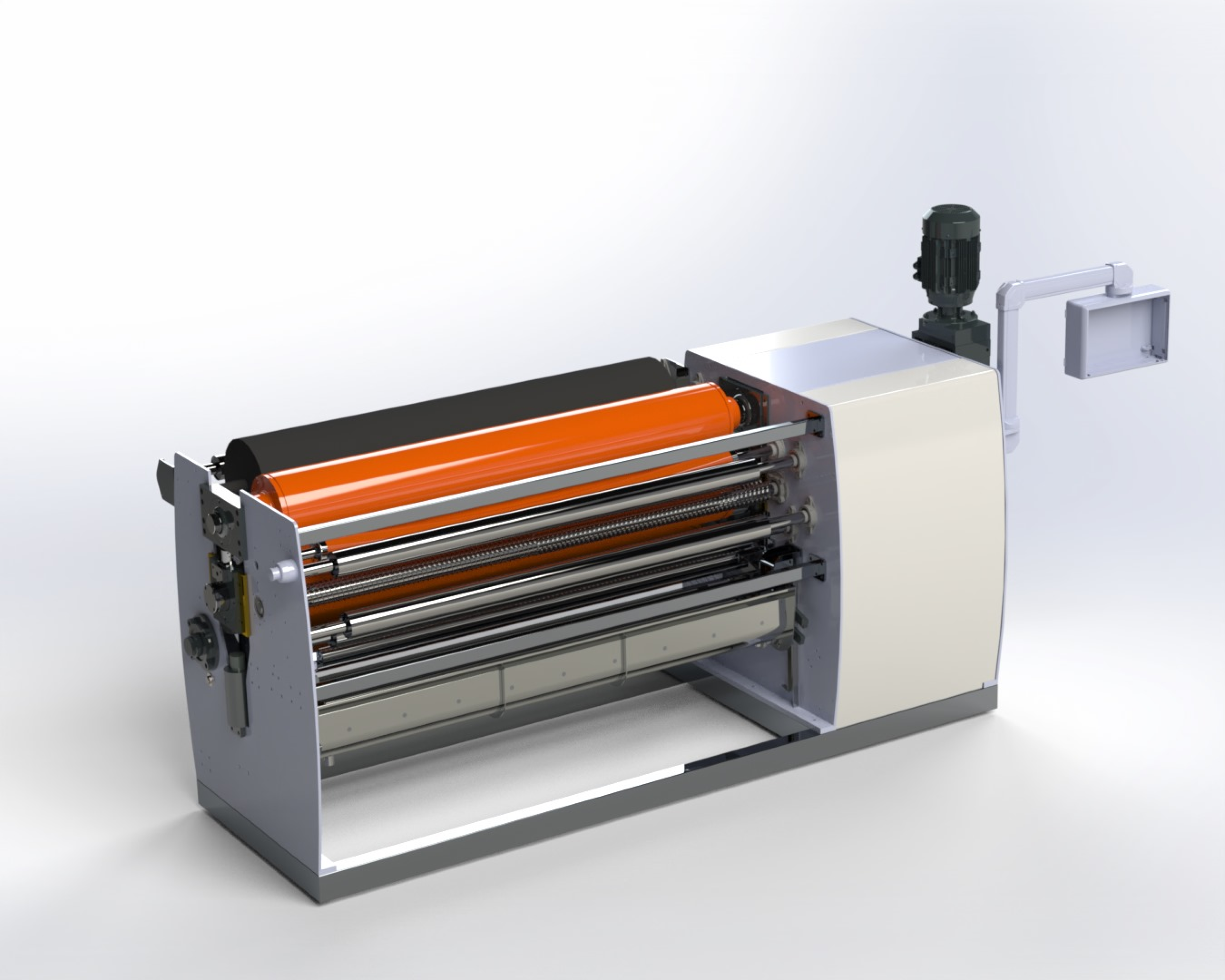

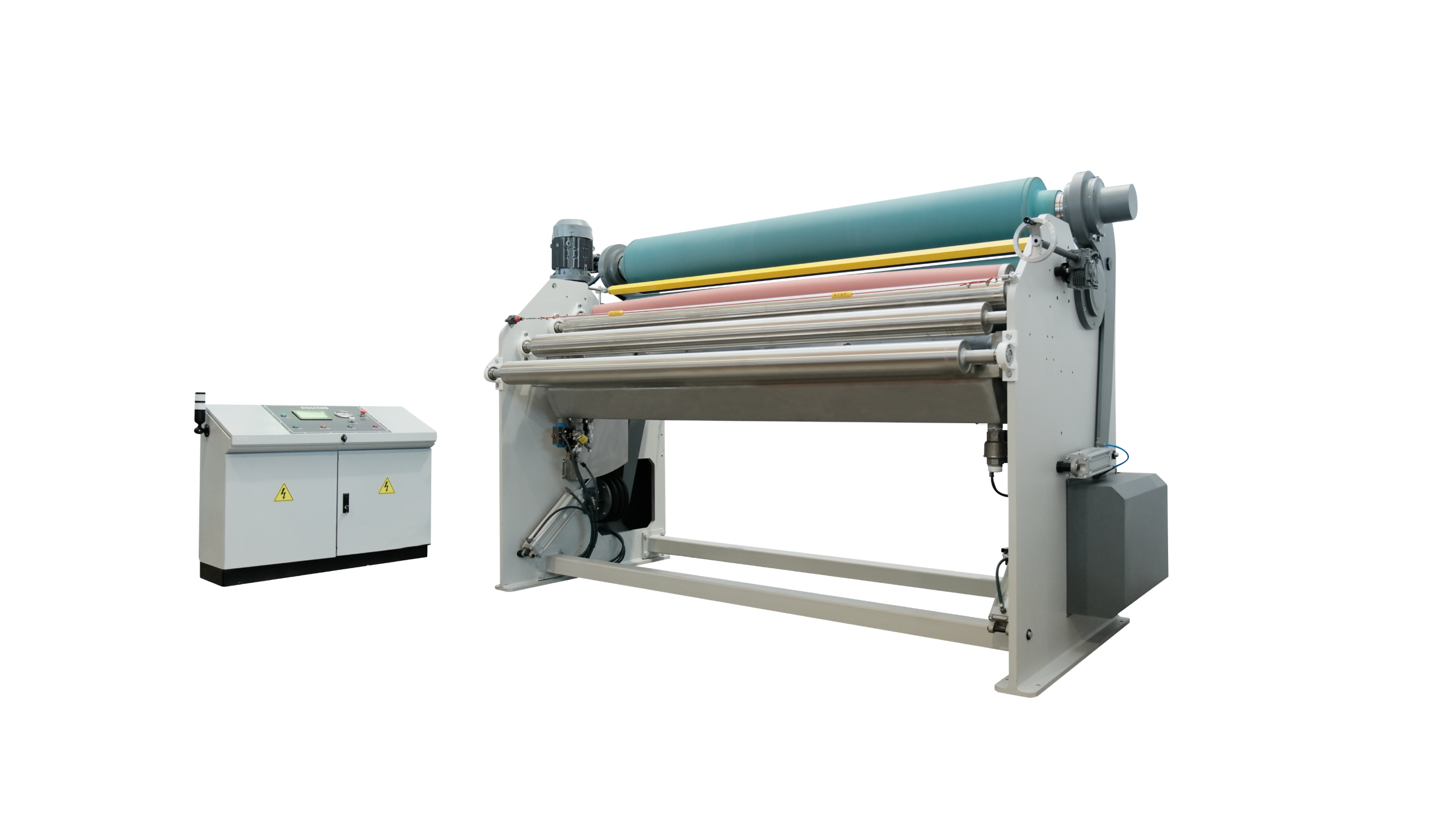

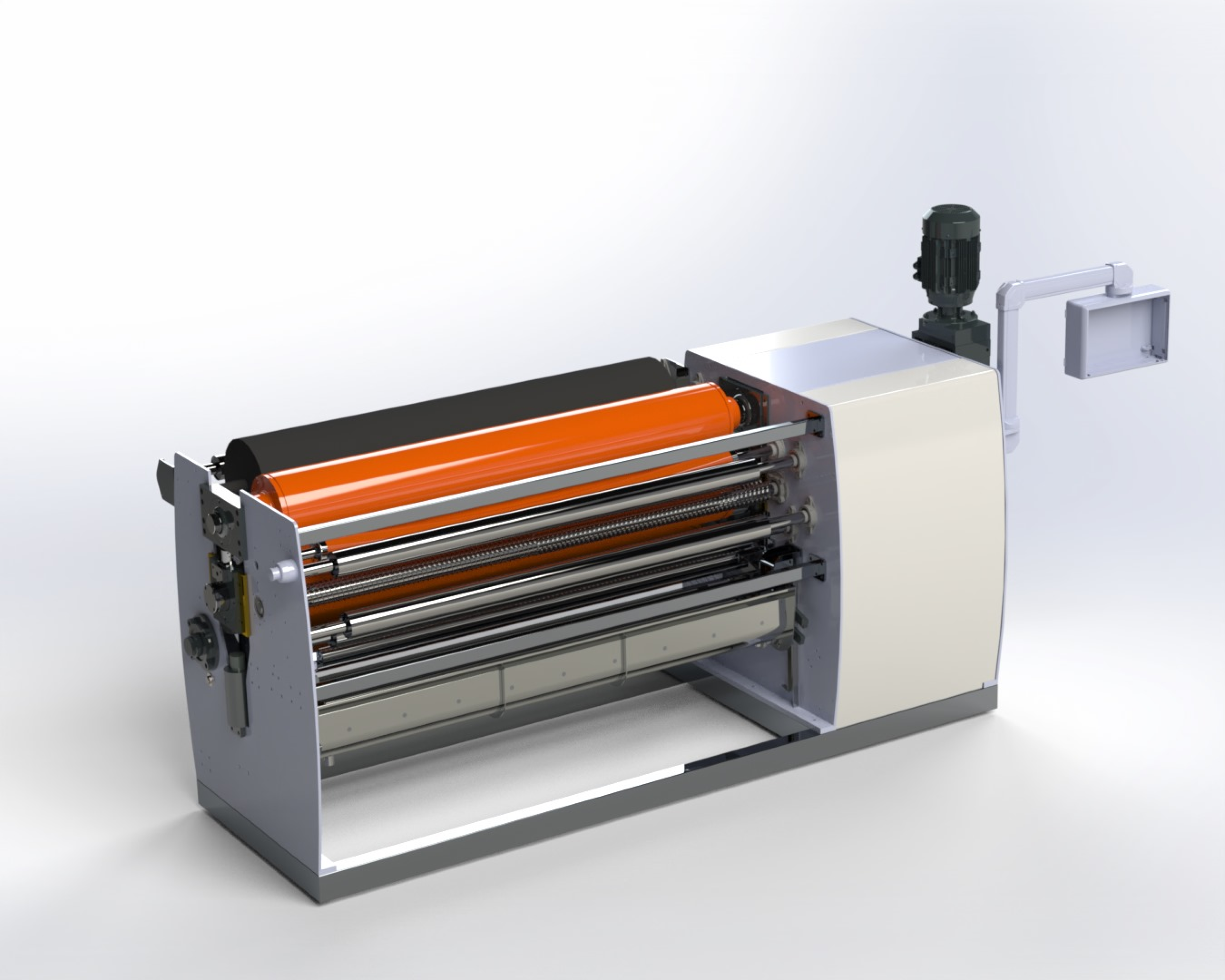

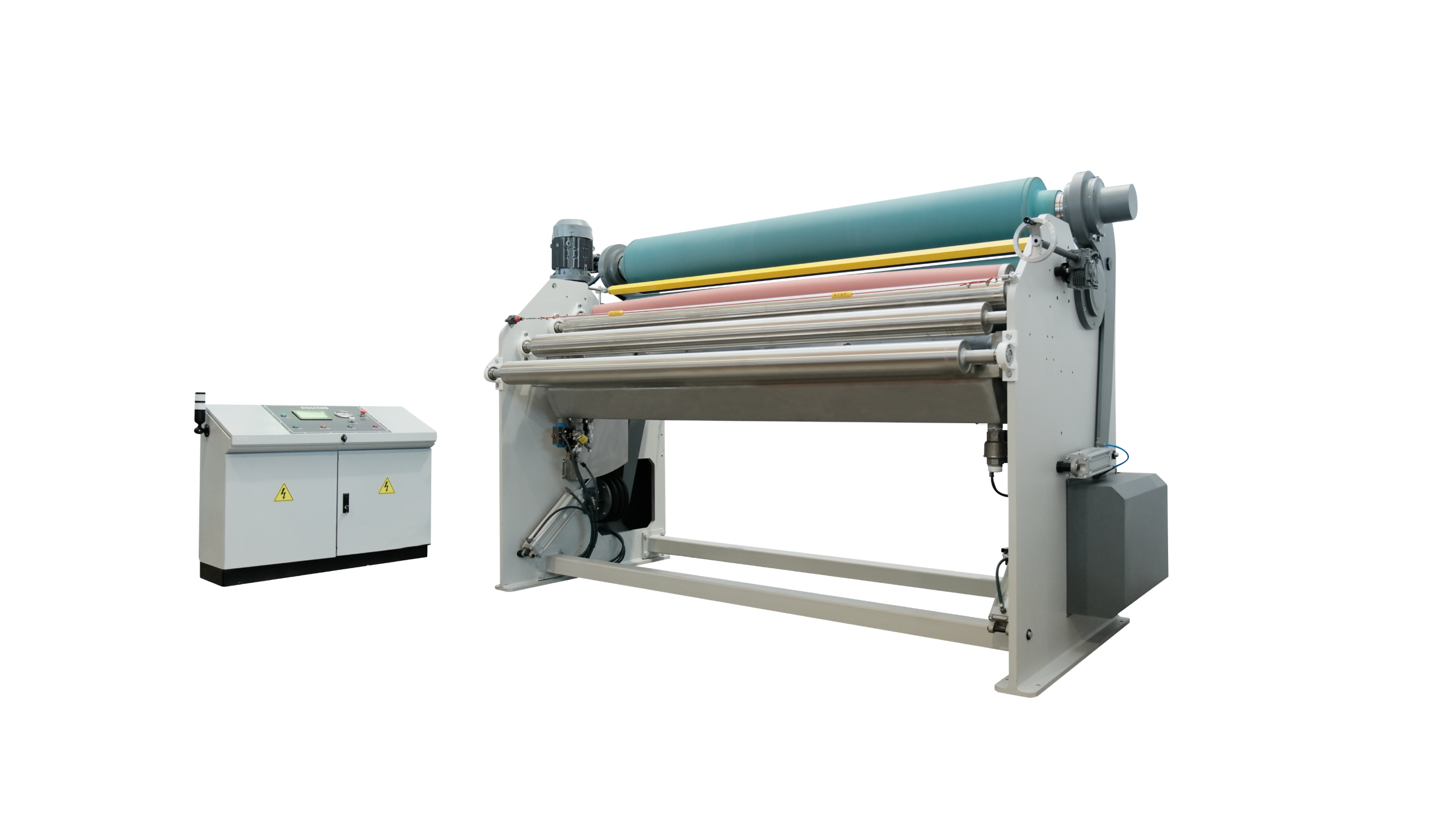

Special rollers designed to have homogeneous squeezing and impregnation throughout the entire width of the fabric. S-Roll, Nippol and Flex Roll systems are used to get optimal squeezing or impregnating results

Special rollers designed to have homogeneous squeezing and impregnation throughout the entire width of the fabric. S-Roll, Nippol and Flex Roll systems are used to get optimal squeezing or impregnating results

| Type Of Machine | Pad-Pro |

| Maximum Working Pressure (kg/cm) | 60 |

| Working Speed (m/min) | 5-90 |

| Maximum Working Width (mm) | 6000 |

| Types of Rollers | Classic / S-Roll / Nippol / Flex-Roll |

Fabric processing needs to be done in a very fine and sensitive way. For this reason, the use of the best and most accurate products for the fabrics in question always brings quality. In order to obtain a quality product, there are processes that every fabric must go through. At the beginning of these processes is moisture.

Moisture is a very important issue for fabrics and needs to be analyzed carefully. Squeezing scarves are one of the most used equipment at this point. The scarves ensure that special processes are applied to the fabric in order for the moisture to reach the ideal position. This squeezing process is provided in such a way that an equal load is applied to each part of the fabric. In this way, there is no deterioration or deformation of the fabric.

The scarves to be tightened can be in special sizes. At this point, the processes required to determine the size can be determined according to the fabric to be processed. Scarves are functional structures that can be used alone or in addition to different machines. The squeezing processes in question are important not only for humidity but also for other situations.

Depending on the type of fabric, it is a very popular and common process to obtain special use by utilizing different features of the padder. The features of the padder you prefer may also vary according to the band. Spinning machines with speed adjustment work in a way that can give higher performance than other machines for efficiency.

Scarves generally have a cylindrical structure. Thanks to this cylindrical structure, equal access is provided to all parts of the fabric. Ensuring equal access is also important for the fabric to complete the processes in a much higher quality. It is one of the most widely used equipment in the textile industry. It can be used as the only equipment to make finer adjustments for special and sensitive fabrics.

Just like every machine used in the textile industry, there may be extra features of the squeezing machines. Squeezing scarves are primarily mobile and multifunctional. Its portable structure and integration with other machines is very valuable. At the same time, the scarves offer trouble-free use by making appropriate adjustments for each fabric type.

In this way, a smooth production can be realized without the need for extra controls during production. In order to realize a homogeneous squeezing process, a work with two cylinders is carried out. While the upper cylinder of these cylinders performs the operation in general, the lower cylinder performs homogeneity control. In this way, the processes are carried out in a controlled and controlled manner.

Squeezing processes are generally for the water and moisture remaining in the fabric. In order for the process to be carried out in the best way, irrigation can be done with the help of spray before the stages are carried out on the rollers. At the same time, there are precautions and interrupter circuits for emergencies during the operation of the rollers and scarves. In this way, in case of a malfunction in the system, the system can perform automatic interruption without damaging the fabrics.

Squeezing machines can be used in every field of textile without any problem. A highly effective system is established by making special adjustments for each fabric. At this point, it is also very necessary to use it during production. The use of squeezing scarves in precision winding systems is extremely high. However, it is a very special equipment for cooling systems.

Scarves are generally preferred as a single piece in large textile production systems. At this point, it would be much more accurate to decide on its use specific to the production system. In the same way, it is important to determine the cylinder criteria specific to the type of use in order to achieve much higher efficiency. Two-featured systems can be preferred for scarves. At this point, the issue that determines the use the most is pressure.

In order for the use of scarves to be clear, the pressure preference must be given correctly. With this pressure, the fabrics in the padder system are wetted. The squeezing pressures of the cylinders are synchronized with these wetting processes and are preferred. It can be used smoothly in every field of textile production.

We focus on providing our partners with the latest technologies and innovative solutions for a sustainable textile industry for the future.

DISCOVERY