Developments in the textile industry come with greater requirements about the quality of the final product. Nippol system allows you to get more reliable fabric calendering results.

Developments in the textile industry come with greater requirements about the quality of the final product. Nippol system allows you to get more reliable fabric calendering results.

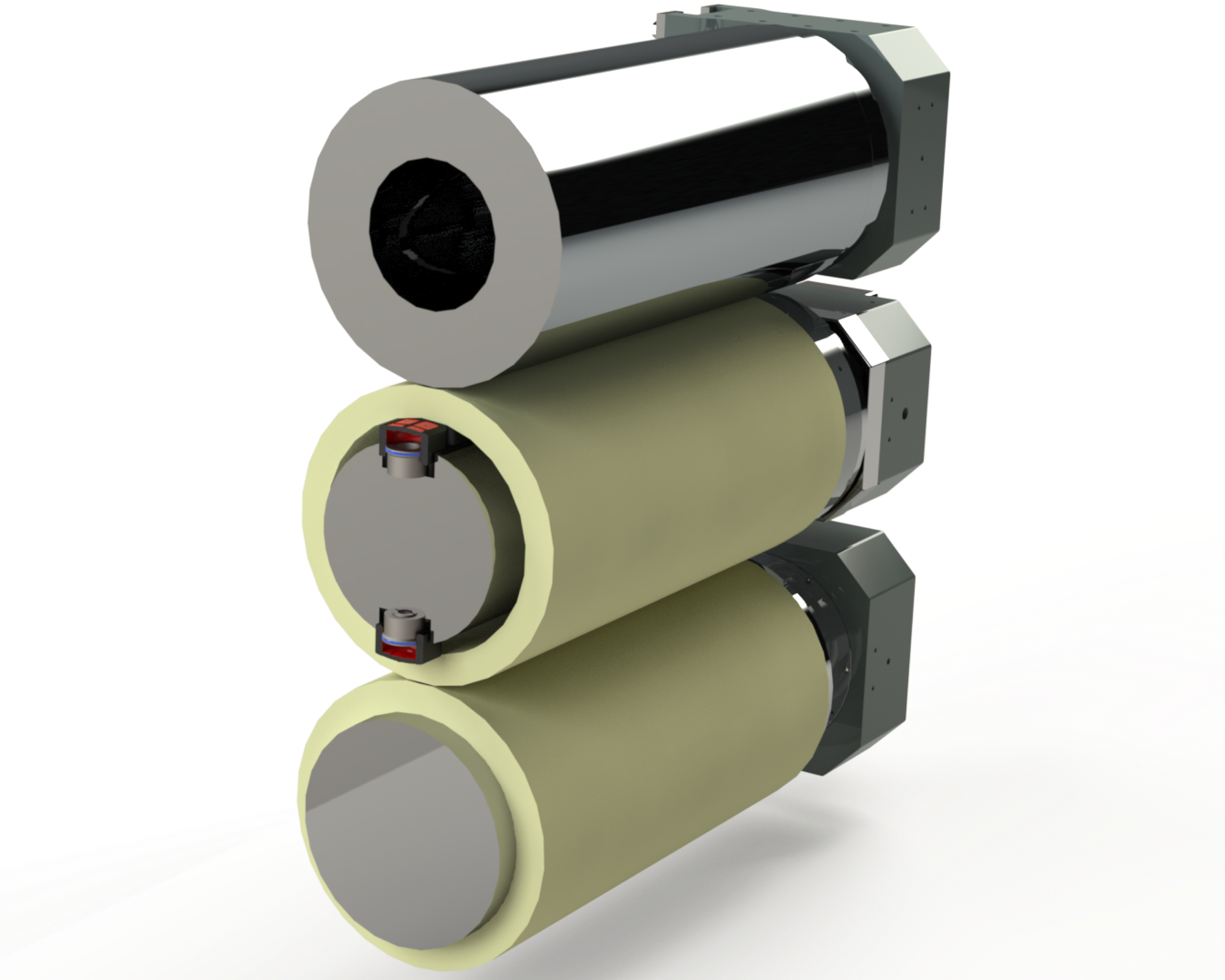

| Type Of Machine | OPTIM | DELUXE | TECH PLUS |

| Working Pressure (kg/cm) | 25-300 | 25-400 | 25-500 |

| Working Speed (m/min) | 5-90 | 5-120 | 5-90 |

| Maximum Working Width (mm) | 8000 | 8000 | 3400 |

| Maximum Working Temperature (°C) | 200 | 250 | 300 |

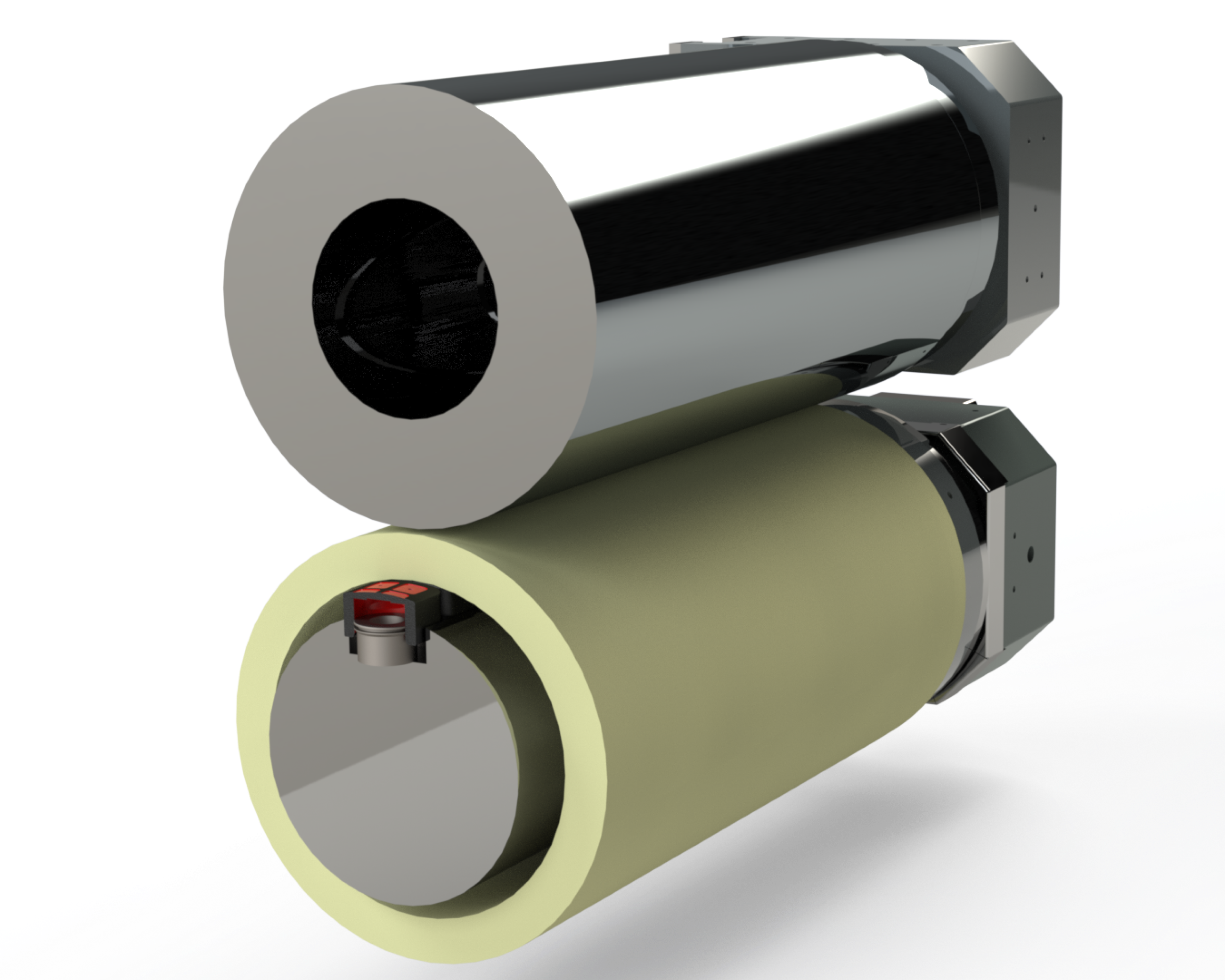

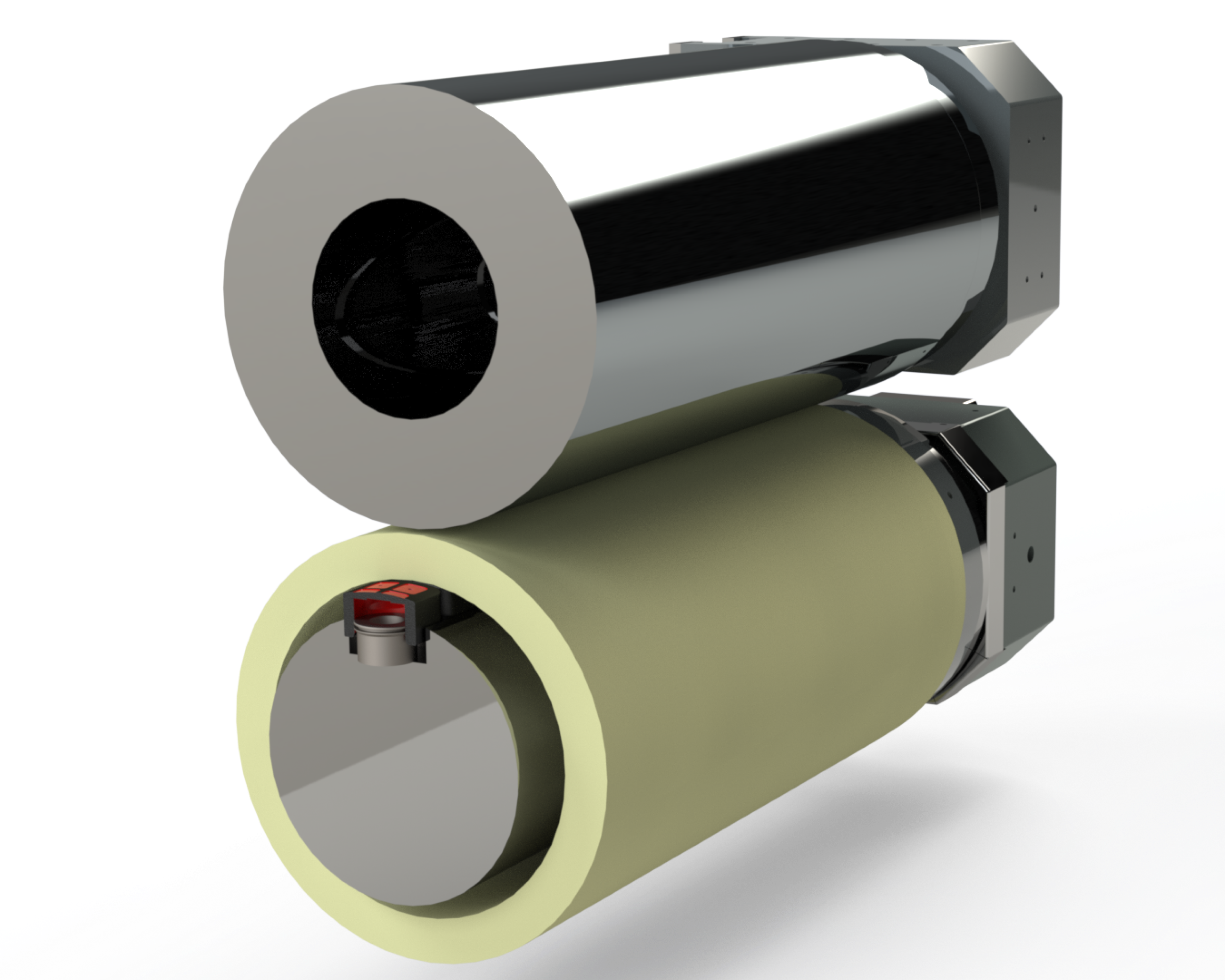

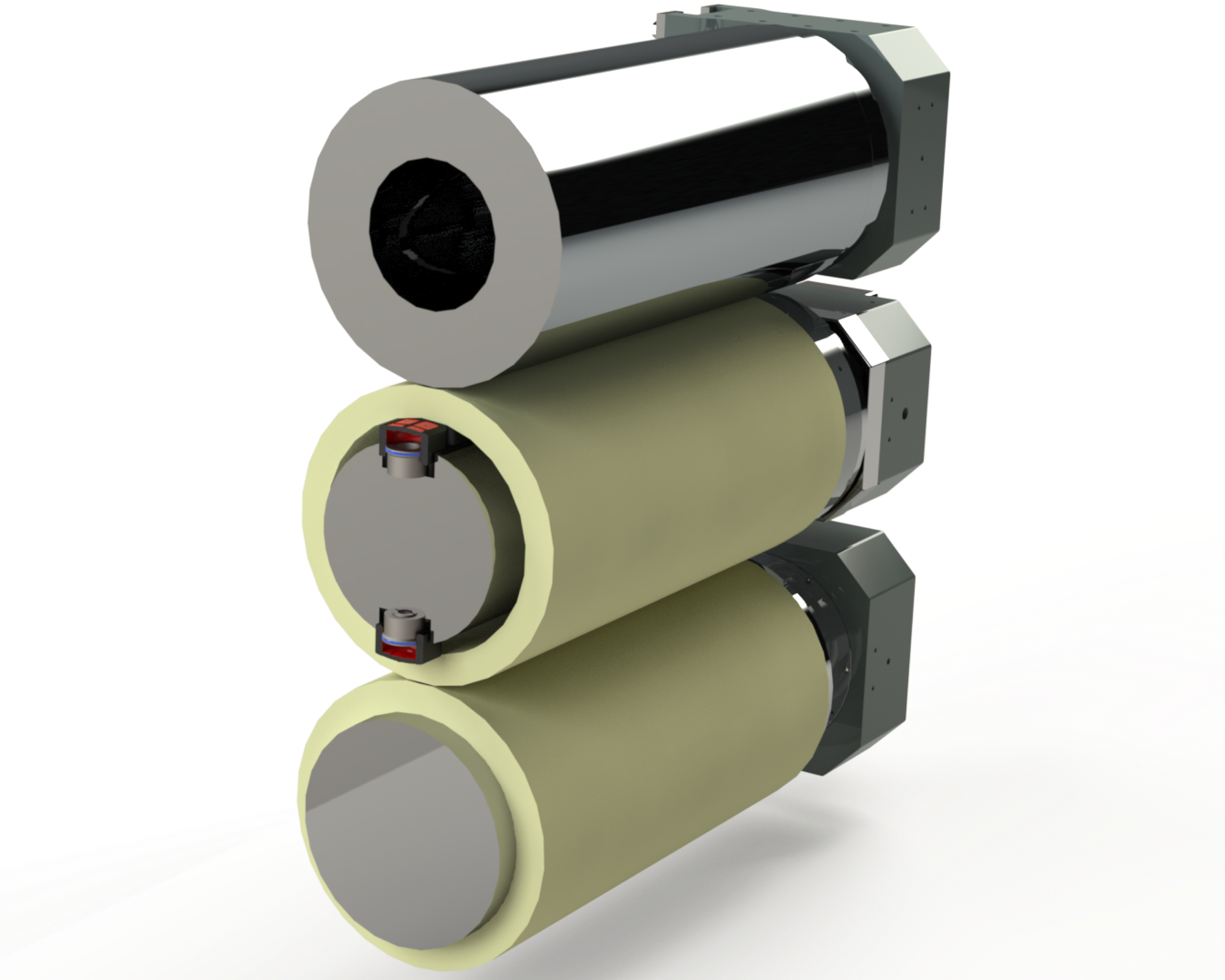

| Types of Nippol Sleeves | Polyamide / Composite |

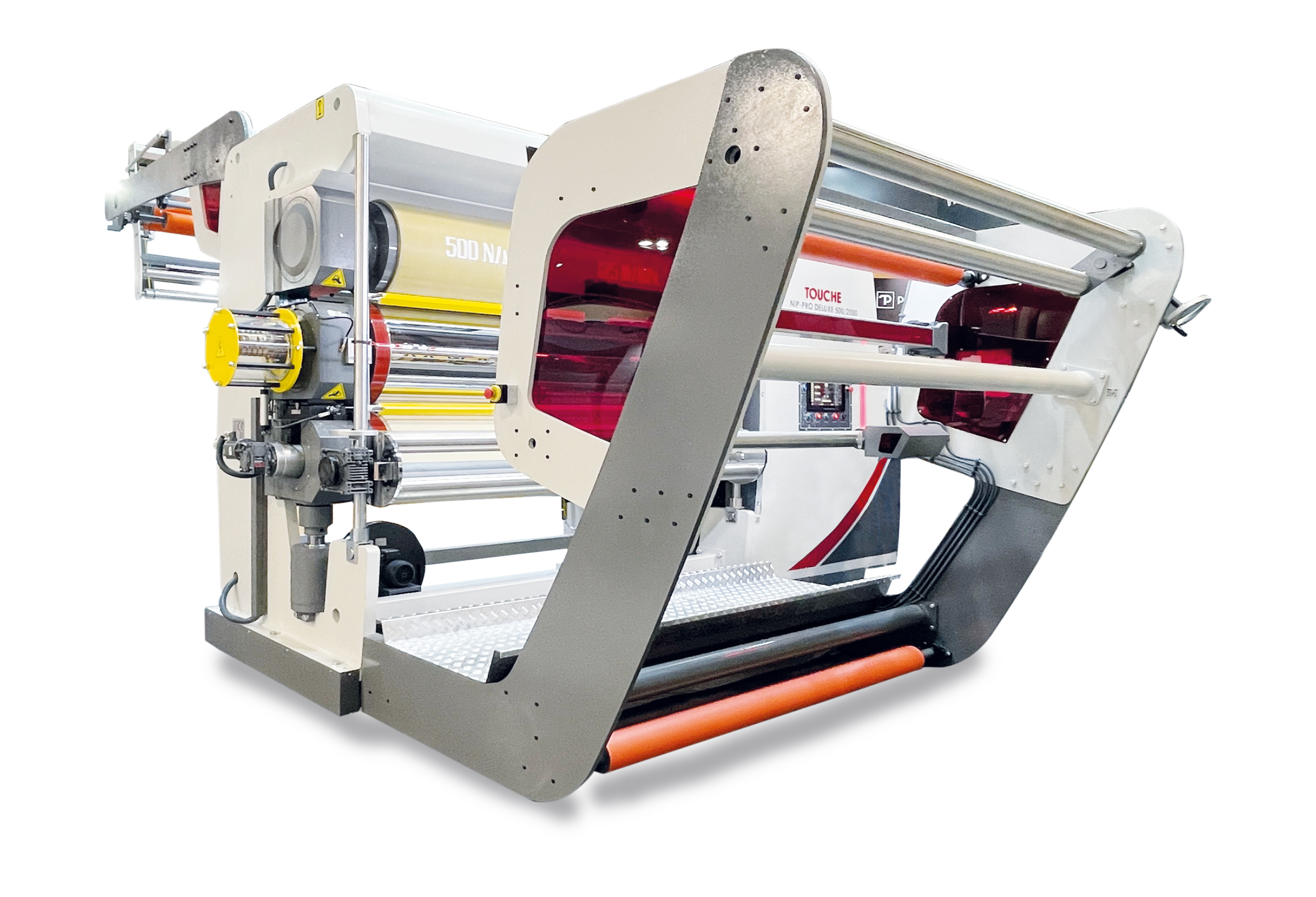

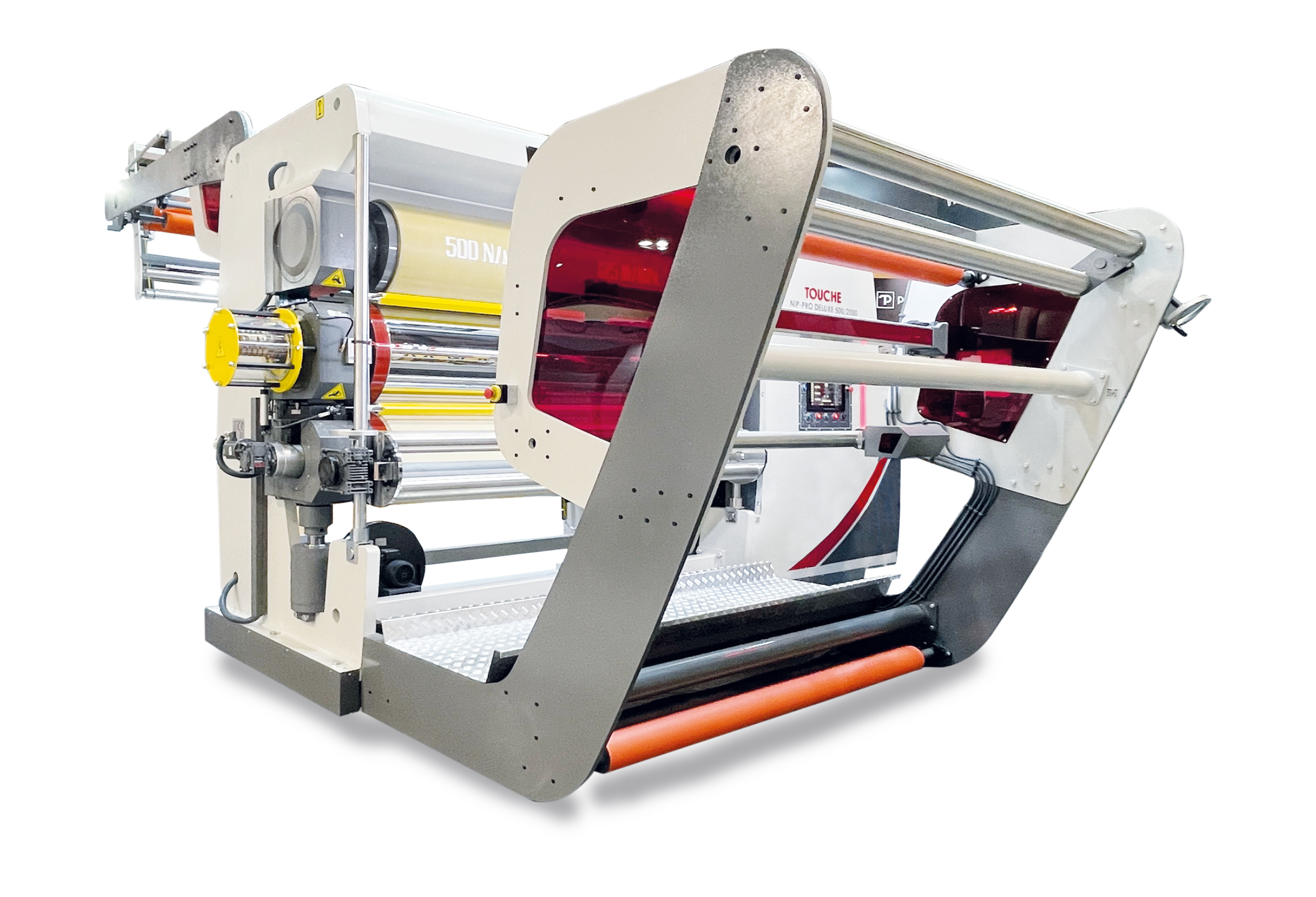

Such machines are of great importance in the growing textile sector. The Nippol machine aims to improve fabric quality and increase productivity. The machine improves these features by processing the fabric. The machine, which is produced in two different ways, is produced at the request of the customer. It has two different options produced with inflatable cylinders and classical way.

The machine is used in a wide and varied way in the textile industry. It is widely used from normal daily clothing products to parachute fabrics. We can say that it is used in very different sectors such as denim fabrics and filter fabrics. While the fabrics are used entirely for daily wear, filter fabrics are produced for industry. We can say that the machine, which works very efficiently, serves many different sectors.

The machine, which stands out as a calender machine, can process many different fabrics. The machine, which can work on different fabrics, serves many different sectors. The machine, which is produced with laboratory studies, is organized according to the customer and produced in a state-of-the-art technology. The machine, which increases the quality, can also process on very durable fabrics. In this way, the machine can also find its place in the textile industry produced for safety. The calender machine can work very effectively in terms of efficiency and versatility.

Nippol Calender, which is a calender machine, can be used in many sectors with its high efficiency and high-level technology. The machine, which finds a place among the textile sector and textile sub-sectors, can be produced in different ways. The machine, which is used to increase quality, also increases productivity to a high degree. The machine, which can work on durable fabrics, can also work on parachute fabrics. Nippol, which draws attention with its versatility among calender machines, can be customized according to customer request. The machine, which can be produced with two different options, is produced according to customer request.

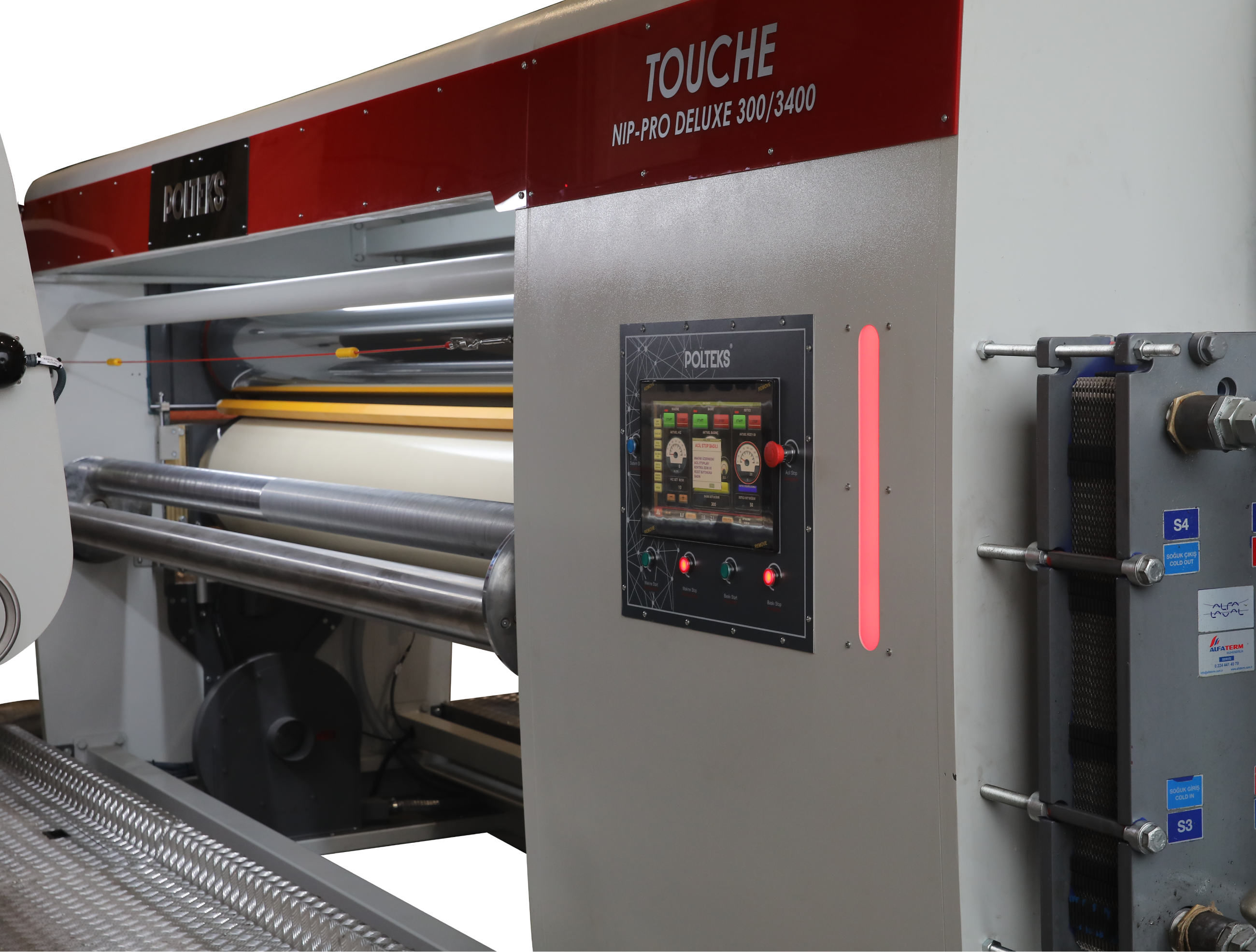

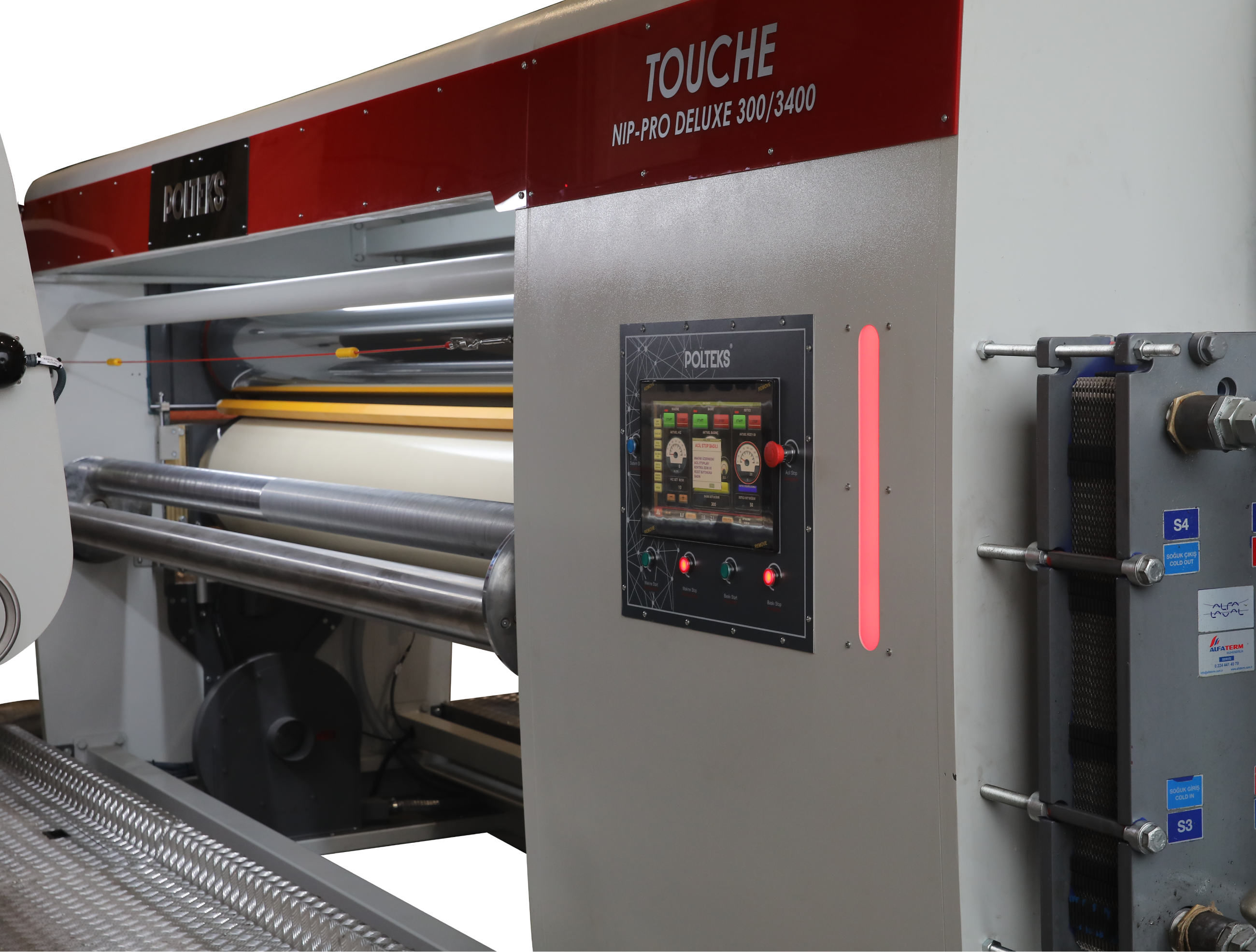

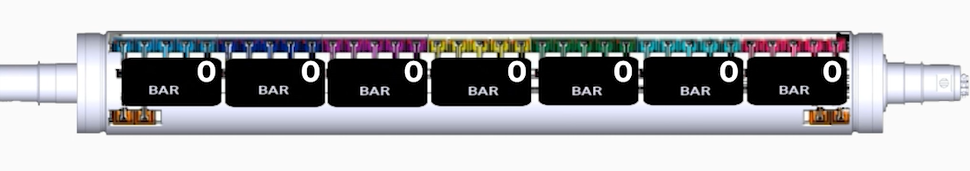

There are many different equipment in the machine. These include a metal detector and an automatic seam control system. The machine also has a heating system that can work in different ways. The steam system, which can heat electrically, dry or oily, can process the fabric. With additional equipment such as an edge gripper system, the machine can work very efficiently. Many different equipment works stably inside. The sensitive tension winding system allows processing without damaging the fabric. At the same time, the static charge accumulated on the fabric is discharged with the static electricity receiver system. The effect system using rubber blanket can work differently on textile materials.

Nippol Calender is a versatile machine that can process almost all textile materials. The sectors used include textile and textile sub-sectors. More differently, we can say that it can work on safety fabrics and parachute fabric. Nippol can find its place in many sectors thanks to its different equipment.

Its ability to process different fabrics makes it usable in many sectors. The machine can also work on everyday textiles such as denim fabrics and shirt fabrics. You can also choose the Nippol machine for pants, jackets and other outerwear fabrics.

The machine, which works precisely, can process different fabrics without damaging the fabric. You can come across the machine in almost all companies working on textile products. The machine, which works on increasing fabric quality with its superior efficiency, is much more advanced compared to calender machines. Equipped with all high-level technologies, you can choose the machine in many different sectors.

| Entry | A-Frame, Plaiter, Central Unwinding |

| Exit | A-Frame, Plaiter, Central Winding |

| Seam Control System | Preceise Seam Control System |

| Metal Detector | Detecting All Types of Metals |

| Tension Control System | Could be integrated to the exit and entry of the machine depending on the need of customer |

| Salvage Shifting System | Moves the fabric left and right to prevents the edges from becoming thick during winding the fabric |

| Edge Holding System | Ensures the fabric to pass through the rollers continuously in straight form. |

| Cooling Rollers | Depending on the fabric passing rollers can be located at the exit or in between the nips |

| Sleeve Cooling System | Cools the sleeve which is in constant contact with the heating chrome roller to prevent deformations on the sleeve |

| Air Permeability System | Inline traversing air permeability system reads air permeability value constantly |

| Reconditioning | Renewing your old machinery to be brand new with hydraulic unit, electrical cabinet, roller maintanence |

We focus on providing our partners with the latest technologies and innovative solutions for a sustainable textile industry for the future.

DISCOVERY