| Entry | A-Frame, Plaiter, Central Unwinding |

| Exit | A-Frame, Plaiter, Central Winding |

| Seam Control System | Preceise Seam Control System |

| Metal Detector | Detecting All Types of Metals |

| Tension Control System | Could be integrated to the exit and entry of the machine depending on the need of customer |

| Salvage Shifting System | Moves the fabric left and right to prevents the edges from becoming thick during winding the fabric |

| Edge Holding System | Ensures the fabric to pass through the rollers continuously in straight form. |

| Cooling Rollers | Depending on the fabric passing rollers can be located at the exit or in between the nips |

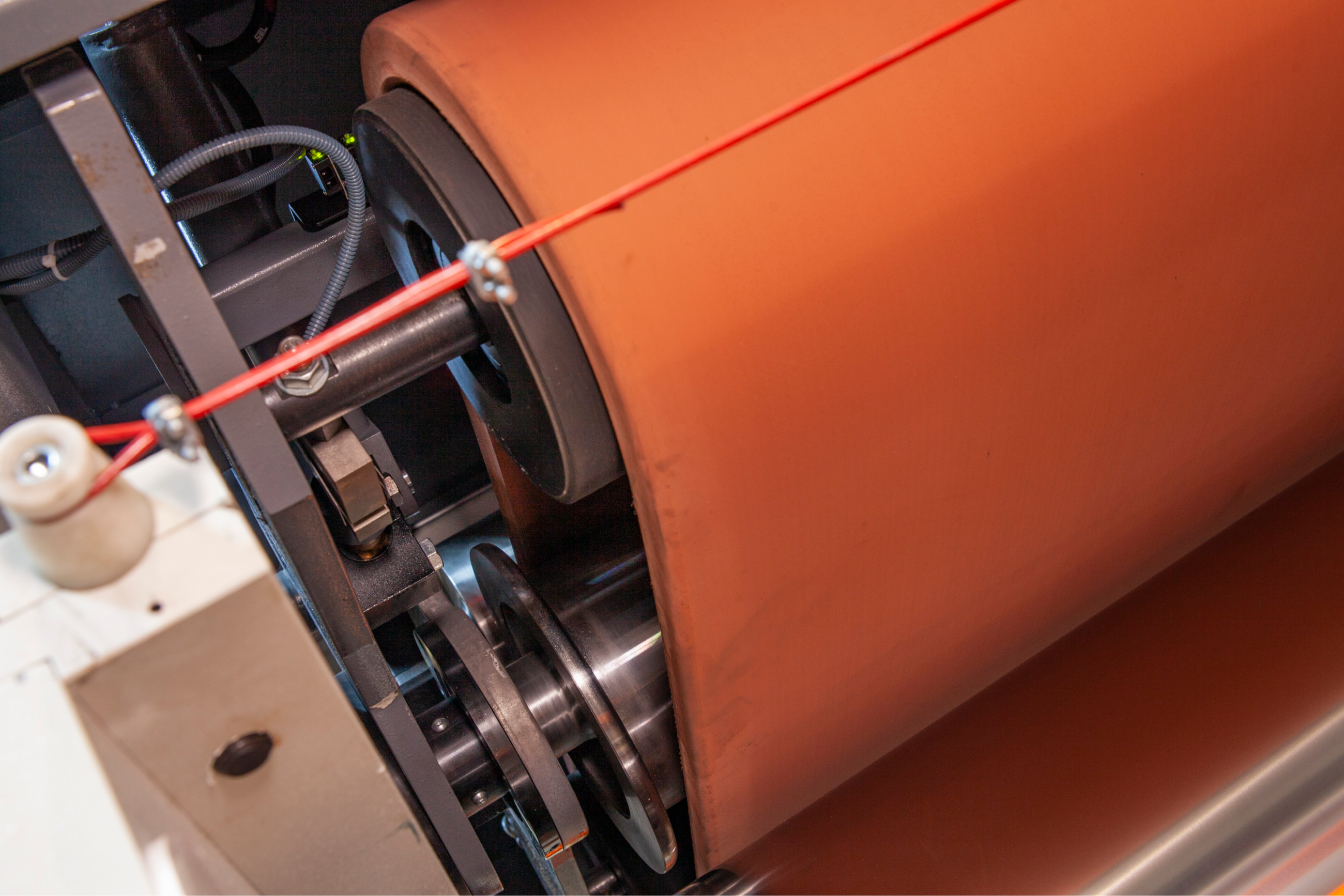

| Sleeve Cooling System | Cools the sleeve which is in constant contact with the heating chrome roller to prevent deformations on the sleeve |

| Air Permeability System | Inline traversing air permeability system reads air permeability value constantly |

| Reconditioning | Renewing your old machinery to be brand new with hydraulic unit, electrical cabinet, roller maintanence |